At Soucy, from processing to molding, several subsidiaries are involved in the rubber manufacturing process for our track systems.

Soucy Techno, our Sherbrooke subsidiary, specializes in rubber preparation. It receives the raw material and adds specific chemical ingredients to give the mixture the desired properties. Our compounding specialist, Denis Dubé, says it's important to choose each ingredient in the recipe in order to offer a customized product that's fit for purpose. The rubber mix is then sent in rolls to Soucy Baron or Soucy Caoutchouc. In turn, our Saint-Jérôme and Drummondville subsidiaries mold the mixture into different shapes. For example, Soucy Caoutchouc will place the rubber compound in high-temperature machines to mold tracks of different sizes, depending on the type of vehicle.

Soucy Techno, our Sherbrooke subsidiary, specializes in rubber preparation. It receives the raw material and adds specific chemical ingredients to give the mixture the desired properties. Our compounding specialist, Denis Dubé, says it's important to choose each ingredient in the recipe in order to offer a customized product that's fit for purpose. The rubber mix is then sent in rolls to Soucy Baron or Soucy Caoutchouc. In turn, our Saint-Jérôme and Drummondville subsidiaries mold the mixture into different shapes. For example, Soucy Caoutchouc will place the rubber compound in high-temperature machines to mold tracks of different sizes, depending on the type of vehicle.

Did you know that the possibilities for rubber recipes are endless? Customized compounds must meet customer requirements, because depending on the type of terrain, the rubber will be put to the test in different ways.

Here are 3 interesting characteristics of rubber made at Soucy:

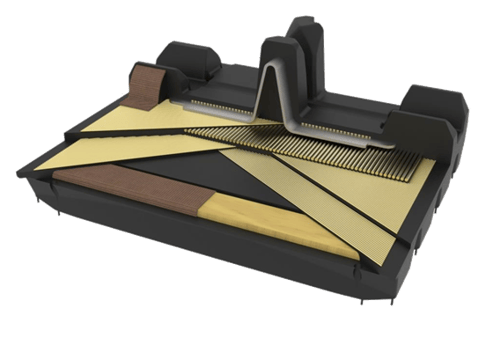

1-Our tracks are multi-layered

The layering of materials and rubber makes our tracks ultra high-performance and resistant. And the term "materials" is well chosen: the tracks are not made of rubber alone! Our materials engineer, Jean François Drapeau at Soucy Caoutchouc, knows the importance of using the right elements to create a quality track that will last a lifetime. If you cut one open, you'll see that it contains steel cord, fiberglass and several types of rubber. Each layer has its own specific role to play.

The layering of materials and rubber makes our tracks ultra high-performance and resistant. And the term "materials" is well chosen: the tracks are not made of rubber alone! Our materials engineer, Jean François Drapeau at Soucy Caoutchouc, knows the importance of using the right elements to create a quality track that will last a lifetime. If you cut one open, you'll see that it contains steel cord, fiberglass and several types of rubber. Each layer has its own specific role to play.

Rubber track cutting

2-Rubber behavior is greatly influenced by temperature

Rubber can become very stiff in the cold, but can soften significantly in the heat. This reality must be taken into account when developing and selecting rubber for our products, and tested at a wide range of temperatures. From the cold of the Canadian Arctic to the extreme heat of the Afghan desert, our rubbers can withstand the most extreme conditions, provided they are well chosen for the conditions in which they will be used. What's more, rubber generates its own heat when subjected to deformation... another challenge in choosing the right materials!

3-Tracks from 5 lbs... to 1.2 tons!

Thanks to the various presses in our plants, we are able to mold a wide range of track sizes. This means that the tracks can be molded without joints, thus avoiding a potential point of weakness during use. Soucy Caoutchouc manufactures snowblower tracks weighing around 5 pounds, motorsports vehicle tracks weighing 15 to 30 pounds, and defense vehicle tracks weighing up to 1.2 tons. That's almost the average weight of a car!

Tracked defense vehicle

Tracked defense vehicle

The manufacture of tracks remains an important part of rubber processing at Soucy, but many other products are made from rubber. These have properties that are customized and specific to the needs of our various customers. To find out more about rubber-related products or track systems, the Soucy website is full of information on the subject.