In September 2020, Soucy Rivalair, along with other Quebec companies, received financial support from the Government of Quebec and Réseau Trans-Al under the Alu4.0 initiative. These investments are part of the digital transformation of Quebec manufacturing companies. In the coming year, Soucy Rivalair will set up a new robotic cell to power production equipment.

This is not the first time Soucy Rivalair turns to robotization. The company made its first leap into automation a few years ago when it acquired two machining centers powered by a PALLETECH robotic supply system.

Advantages of a robotic system for machining

The PALLETECH system consists of a handling robot, a two-level modular storage system and a parts loading/unloading station. It is one of the best automated machining technologies on the market. This technology brings many advantages to the day-to-day operations.

1. Increase in equipment utilization rate

In order to increase the equipment utilization rate, a robot manages the storage and handling of parts entering and leaving the machining center. This reduces downtime and allows machining in lights-out mode, without the need for human intervention.

2. Value-added tasks for machinists

Traditionally, machinists waste a lot of time assembling and disassembling the various tools used to machine a production batch. These interventions cause machine downtime and require qualified workers to spend time on a task that can be automated.

With an automated supply system, it is possible to have several machining fixtures at all times. This increases the efficiency of high-mix and high-volume production.

3. Automation of machining processes

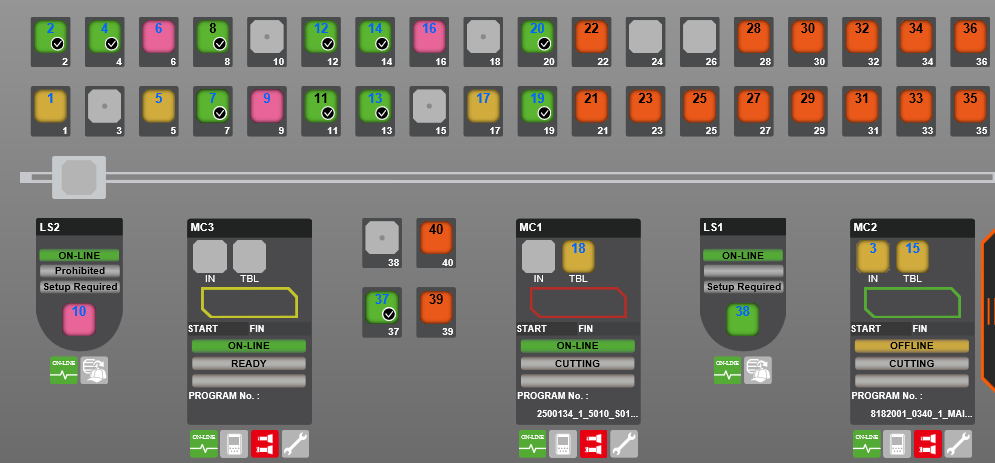

The PALLETECH control system is also a reference in Industry 4.0. It allows to sequence production, monitor operations, and even track tool lifespan.

The automated system also includes several other assets:

- Allows a single employee to operate several machines.

- Allows operations to be carried out completely unattended.

- Prioritizes urgent jobs without having to reorganize the rest of the workload.

- Increases pallet storage capacity while minimizing floor space.

- Reduces inventory and provides just-in-time production.

- Connects different types of Mazak machine tools to create a fully automated manufacturing cell.

Equipment tailored to the company

Another interesting characteristic is its modular construction which allows PALLETECH to evolve with the company. For instance, in winter 2020, Soucy Rivalair increased the cell's capacity. The PALLETECH was doubled to bring the number of pallets in operation to 40. A loading/unloading station and a third machining center were added to the cell. Soucy Rivalair is now ready to increase its capacity!

Beyond the equipment, a team of employees was mobilized to set up, operate and improve processes. Fixtures, programs, inspection, handling, final touch... everything has been reviewed in order to reach the targeted pace.

In the end, this acquisition created new jobs at Soucy Rivalair. These jobs are focused on high value-added elements that require human expertise.

For Soucy Rivalair's clients, robotic machining is a guarantee of quality and respect of commitments. Quality is stable, human error is minimized and the resulting productivity ensures a competitive price.

To learn more about our machining solutions, visit our expertise page.